Choosing a pressure washer that fits your needs is not that easy. You need to keep an eye on many things like its purpose, frequency of use, surface material where you will use it, and your budget. You also have to understand contrasting features like hot or cold water, electric or gas, and belt or direct drive technology.

If you mix all the factors above with other specs like PSI (pounds per square inch) and GPM (gallons per minute), choosing becomes even more complicated. To make it easier, you have to understand the pros and cons of each type, like in the case of a direct vs. belt drive pressure washer.

Direct Drive Pump

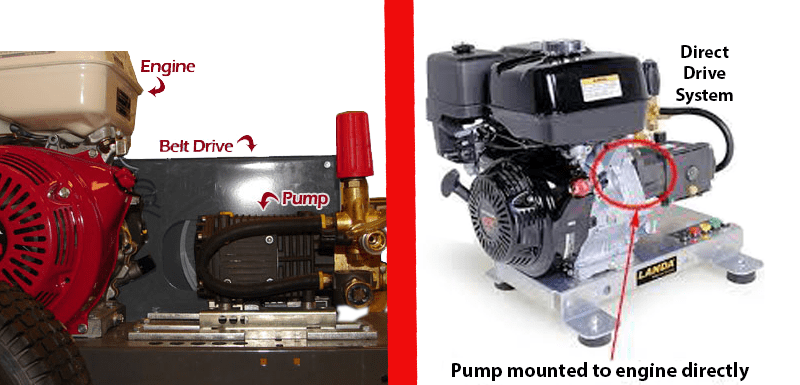

A pressure washer with a direct drive pump has simpler mechanisms. In this setup, the pump is directly mounted on the motor.

Pros

- In terms of price, the direct drive is cheaper than the belt drive model. The reason is apparent- because it doesn’t have extra parts used by its counterpart.

- It’s more compact, which makes it ideal if you’re going to work in a tight space.

- Provides powerful blasts to quickly get rid of stubborn dirt.

Cons

- More vulnerable to wear and tear. Because of its design, the direct-drive pump spins faster compared to the belt drive pump. Since the pump is connected directly to the motor, the engine’s number RPM (revolutions per minute) is the same RPM on the pump. This mechanism tends to wear out the pump faster, resulting in more maintenance costs on your part.

- Things that happen to the motor directly impact the pump, and vice versa. If the engine is damaged, there is a big possibility that the pump is also damaged.

Belt Drive Pump

A pressure washer that uses a belt drive system has a pump not mounted directly into the motor. Instead, the pump and the motor are connected by a pulley system.

Pros

- Less maintenance is needed. Since the pump is not mounted on the motor, it’s not susceptible to the engine’s vibrations. In this type of setup, the belts and pulleys take some of the vibrations before it reaches the pump. Reduced vibrations can lead to lesser maintenance costs.

- Less heat production. The pulley system lessens the RPM. With minimal heat produced, the pressure washer itself will be in good condition for a long time.

- It can be used regularly. This is why a pressure washer with a belt drive technology is commonly used by most business owners, especially those engaged in professional cleaning services.

- Can make use of the water and cleaning detergent more efficiently.

Cons:

- Costs more during the initial purchase. But this can be offset by less maintenance cost in the long run.

- Longer strokes and increased stroke time. Because of reduced RPM, the pressure washer produces less powerful blasts, leading to a longer cleaning time.

Now that you understand the differences and the advantages and disadvantages of each pump system, you can properly decide which one to buy. A quick tip: direct drive is preferable if you only use a pressure washer periodically. However, if you own a business or have a professional cleaning service company, go for a belt drive pump model.